-

Menu Close -

Search now

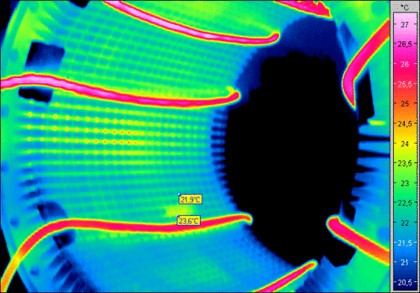

detects anomalies and weak points quickly and reliably

Our thermal imaging cameras quickly and reliably detect anomalies and weak points in materials and components. Thermal bridges in buildings as well as damage or overheating in drives, switchgear and industrial plants can be detected without contact using the imaging method.

Whereas other methods require large areas of piping and pipe systems to be exposed, a single glance is sufficient with the thermal imaging camera.

e.g. drives, switch cabinets, fire prevention on electrical systems, support in preventive mechanical maintenance, inspection management for large production plants, detection of poorly insulated components, etc.

Wir verwenden Cookies, um Inhalte zu personalisieren, Funktionen für soziale Medien bereitzustellen und unseren Datenverkehr zu analysieren. Wir geben auch Informationen über Ihre Nutzung unserer Website an unsere Partner für soziale Medien und Analysen weiter, die diese möglicherweise mit anderen Informationen kombinieren, die Sie ihnen zur Verfügung gestellt haben oder die sie durch Ihre Nutzung ihrer Dienste gesammelt haben. Sie stimmen unseren Cookies zu, wenn Sie unsere Website weiterhin nutzen.