-

Menu Close -

Search now

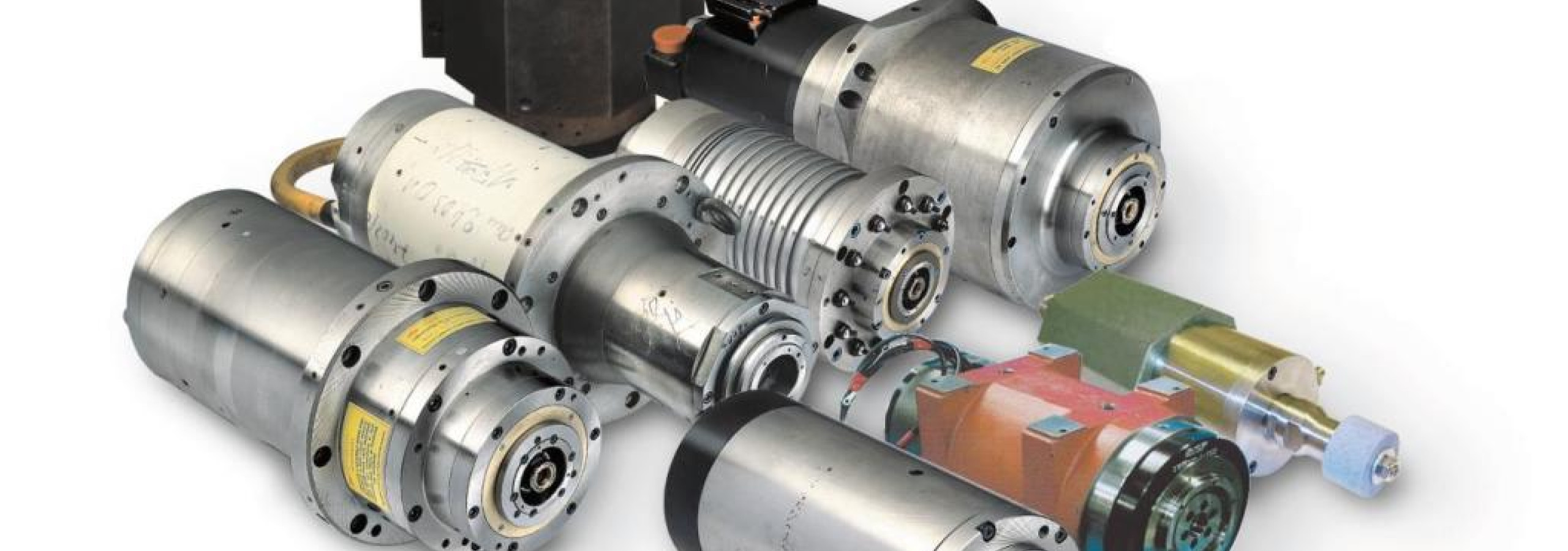

Spindle service, repair, reconditioning and upgrades of all spindle designs and brands.

All spindle types, All spindle brands, All spindle applications.

KRAUTER - Spindle Service ensures more efficient machine tools. In cooperation with SKF, we offer not only reconditioning, but also optimisation on request.

We require: Machine manufacturer, spindle manufacturer, spindle model, rotational speed

Your advantage:Free pick-up service nationwide in regular traffic Fixed price - guarantee after cost estimate, exchange motors from stock.

Wir verwenden Cookies, um Inhalte zu personalisieren, Funktionen für soziale Medien bereitzustellen und unseren Datenverkehr zu analysieren. Wir geben auch Informationen über Ihre Nutzung unserer Website an unsere Partner für soziale Medien und Analysen weiter, die diese möglicherweise mit anderen Informationen kombinieren, die Sie ihnen zur Verfügung gestellt haben oder die sie durch Ihre Nutzung ihrer Dienste gesammelt haben. Sie stimmen unseren Cookies zu, wenn Sie unsere Website weiterhin nutzen.